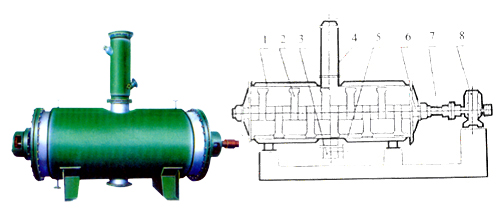

| The drier features simple structure, easy operation, long use period, stable performance, low consumption of vapor, good adaptability and excellent quality, especially applicable for paste materials that are of low temperature tolerance, low burning point and fast oxidization. This device has stood test of time. Theory: To-to-dried matters enter from top of the device, and are made to move back and forth shaft-ward by reverse and diverse stirring the rake, touching the inner wall of the body, heated constantly by steam and shredded to shake off the water on the matters. The vaporized water is drained out at pump outlet after going through dry duster, wet duster and condenser. Structure: main parts of vacuum rake dryer. |

1、Shell 2、Finger 3、Output Devices 4、Feeder 5、Smash rods 6、Seal

7、Stir axis 8、Transmission device

Stores

Slurry form High sauce Following a 100 Stores Various pigments 、Soil-like material Soda centrifuges and filter and filter detergent, starch stone base, dyes pigments, such as clay cement gray clay

Applications under appropriate conditions

Following a 100 solution synthetic fiber materials, liquid crystal vacuum, emulsion sweet potato chips, minerals and Suspensions

Type and technical characteristics

Main parameters of models

|

Nominal capacity |

|

|

|

|

|

Material |

Weight |

Electrical power |

Length x width x height dimension

|

| |

Jacket |

XPG0.5 |

0.5 |

1.86 |

0.2 |

0.021 |

0.686 |

435 |

15-20 |

|

|

Note:3 |

|

Fu:5.5 |

XPG1 |

1 |

6 |

0.75 |

0.021 |

0.686 |

435 |

9 |

A3 |

3400 |

5.5 |

3700×945

×3270 |

1Cr18Ni9Ti |

3300 |

XPG2 |

2 |

8 |

1.2 |

0.021 |

0.588 |

425 |

9 |

A3 |

4900 |

11 |

4570×1130

×3455 |

1Cr18Ni9Ti |

4800 |

XPG3 |

3 |

11.5 |

11.5 |

1.021 |

0.588 |

425 |

9 |

A3 |

6400 |

15 |

6076×1130

×2980 |

|